【Capacity】:0.5-15t/h

【Finial size】:80-400mesh

【Processible Materials】:Limestone, calcite, barite, dolomite, potassium feldspar, marble, talcum, gypsum, kaolin, bentonite, medical stone, rock phosphate, manganese ore, iron ore, quartz, active carbon, carbon black, ceramic, coal, etc.

【Application】:Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics

◆ The whole plant is vertical structure of strong systematic characteristic, so it occupies small area. From crushing of raw material to grinding and packing is an independent production system.

◆ Compared with other milling plants, its passing ratio achieves 99%, this is what other mill can not reach.

◆ Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

◆ Main parts of the whole plant are made from cast and steel of high quality. The technics is so subtly that insures the durability of whole plant.

◆ The electric control system is centralized controlled, so the automaticity is high, no people are needed in the operating room

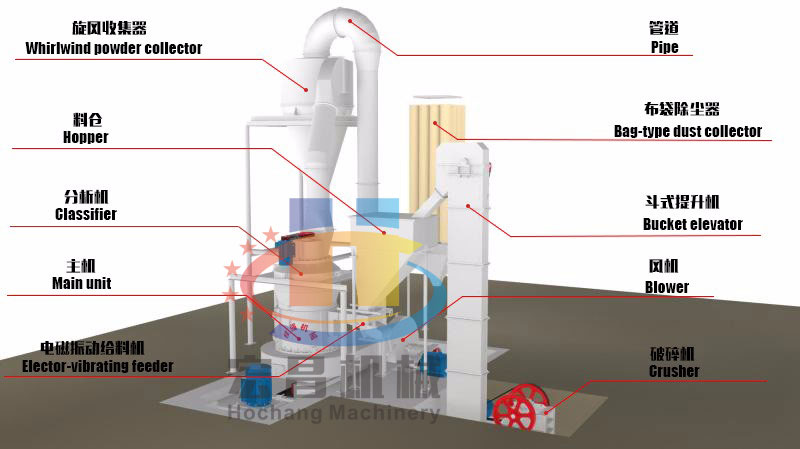

4. Working Principle of Grinding mill plant◆ Raw material is crushed by jaw crusher to the size required which is suitable for the Raymond Mill (Grinding Mill) ,

◆ Then the crushed materials are elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for grinding mill. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between ring and roller to accomplish the grind.

◆ After this, the ground stuff are carried by the air from the blower into the powder separator (Analyzer Machine) for screening. The fine powers are blow into the cyclone powder collector and are poured out through the output-powder valve as the final products, and the corase stuff after the screening will be recycled back into the grinding chamber for regrinding. The set’s airflow system is closely sealed up and circulated under condition of negative and positive pressure.

5. Technical parameter of Grinding mill plant

| Model |

Roller (pcs) |

Roll Dia. (mm) |

Roll Ring Size (mm) |

Max. Input Size (mm) |

Output Size (mm) |

Capacity t/h |

Power (Kw) |

Dimension (mm) |

| 3R2115 | 3 | 210*150 | 630*150 | 15 | 0.125-0.044 | 0.4-1 | 15 | 3500*3300*4500 |

| 3R2615 | 3 | 260*150 | 780*150 | 20 | 0.125-0.044 | 0.5-2 | 18.5 | 4650*3600*5100 |

| 3R2715 | 3 | 270*150 | 830*150 | 20 | 0.125-0.044 | 0.8-3 | 22 | 4700*3600*5100 |

| 4R3016 | 4 | 300*160 | 890*160 | 25 | 0.125-0.044 | 1-4 | 30 | 5400*4100*5200 |

| 4R3216 | 4 | 320*160 | 970*160 | 25 | 0.125*0.044 | 1.8-4.5 | 37 | 7100*5900*7900 |

| 5R4119 | 5 | 410*190 | 1270*190 | 30 | 0.613-0.044 | 2.5-9.5 | 75 | 9200*7250*9700 |

Notice: Any change of Grinding mill plant technical data shall not be advised additionally.

6 Safety GuaranteeZhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

Here is our best selling product.