【Feed Size】:≤200-≤350mm

【Capacity】:5-150m³/h

【Power】:11-480kw

【Application】:To crush medium-hard or brittle materials with hardness not more than 300Mpa and 15% moisture, such as coal, cement, gypsum, alumen, brick, tile, limestone, etc.

| NO. | Parts | Material |

| 1 | Frames | Q235 |

| 2 | Rotor | ZG35B |

| 3 | Main Shaft | 45/35SiMn |

| 4 | Hammers | ZGMn13 |

| 5 | Impact plates | 35SiMn |

| 6 | Side liners | ZGMn13 |

| 7 | Screen | ZGMn12/ZGMn13 |

1. Hammer breaker has advanced designing technology, compact structure and shock resistance

2. Hammer crusher has big feeding material particle size, high rate of finished products, good particle shape

3. Strong crushing ability; rough, medium and fine crushing can be finished in one step.

4. Increasing yield by 30% on year-on-year basis, reducing needle and flake shaped and powdery products by 20%, more energy saving

5. The hammerhead and the sieve plate are made of manganese alloy with strong shock resistance and abrasion resistance.

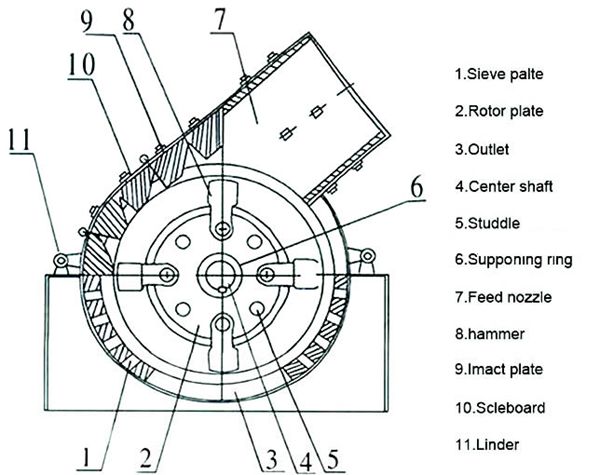

4. Working Principle of Hammer Crusher

|

Model Specification |

Feeding Size (mm) |

Discharging Size (mm) |

Capacity (m³/h) |

Motor power (kw) |

Total weight(t) |

Dimensions (L×W×H)(mm) |

| PCΦ400×300 | ≤200 | ≤25 | 5-10 | 11 | 0.8 | 900×670×860 |

| PCΦ600×400 | ≤250 | ≤30 | 10-22 | 22 | 2.26 | 1200×1050×1200 |

| PCΦ800×600 | ≤250 | ≤35 | 18-40 | 55 | 4.8 | 1310×1180×1310 |

| PCΦ1000×800 | ≤350 | ≤35 | 25-50 | 75 | 5.9 | 1600×1390×1575 |

| PCΦ1000×1000 | ≤350 | ≤35 | 30-55 | 90 | 8 | 1800×1590×1775 |

| PCΦ1200×1200 | ≤350 | ≤35 | 50-80 | 132-160 | 19.2 | 2060×1600×1890 |

| PCΦ1400×1400 | ≤350 | ≤35 | 50-100 | 280 | 32 | 2365×1870×2220 |

| PCΦ1600×1600 | ≤350 | ≤35 | 100-150 | 480 | 37.5 | 3050×2850×2800 |

Zhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

Here is our best selling product.