Our Value Message is “QUALITY IS OUR CULTURE .”

“WITH US YOUR MONEY IN SAFE AND YOUR BUSINESS IN SAFE!”

1 .Competitive advantage Products

2.Confidentially Agreement“ Business Secret CONTRACT”

3.Quality Assurance CONTRACT

4.SMALL Order welcomed

5.After sales services 24x7

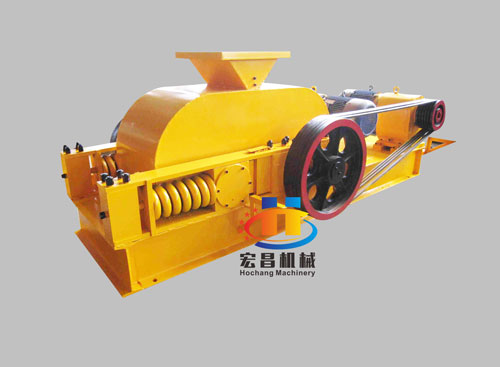

Roller crusher Overview

1 Brief Introduction

Roller crusher is mainly used for secondary and fine crushing to materials below middle hardness, such as coking coal, clinker mineral, limestone, metallic and nonmetallic ore. Roll crusher is available for ore dressing, chemical, cement, refractories, abrasive, building materials industries, finely crushing all kinds of ore and rock below the high, medium hardness,which can make the minimum grain size below 100 mesh,especially in the building materials industry to produce melon meters stone and green bean products etc, and have the more excellent effect than general stave machinery , in recent years, also widely used in crushing steel grit industries.

2. Structure info.(Including Base Materials)

Roller crusher is mainly combined by foundation, frame, crushing rollers, shafts, adjusting device, protective springs, pulleys.

|

NO. |

Parts |

Material |

|

1 |

Foundation and frame |

Q235 |

|

2 |

Rollers |

ZGMn13 |

|

3 |

Shafts |

40Cr/15CrMn |

|

4 |

Springs |

60S2Z2 |

3. Features of Roller crusher

1.It's available for ore dressing, chemical, cement, refractories, abrasive, building materials industries;

2.Roll crusher has the more excellent effect than general stave machinery;

3.Finely crushing all kinds of ore and rock below the high, medium hardness,which can make the minimum grain size below 100 mesh;

4.Roller crusher is stable operation, easy maintenance, low cost, output size adjustable.

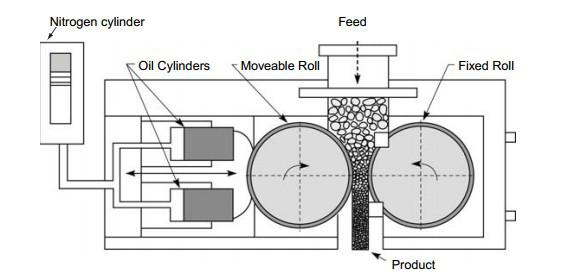

4. Working Principle of Roller crusher

Adjustment of the discharging materials: wedge-shaped or gasket adjustment device is installed between the two rollers; adjusting bolt is installed on top of the wedge-shaped device, and when the wedge is pulled up by the adjusting bolt, it will push the dynamic roller pulley away from the fixed pulley, thus making space between the rollers wider and particle size bigger;

when the wedge moves down, the dynamic roller pulley is pressed by the hold-down spring and then the space gets smaller as well as the particle size. The gasket device works depending on the adjustment of the number and the thickness of gaskets. When adding more gaskets, space between rollers and the particle size will become big; vice versa.

5. Technical parameter of Roller crusher

|

Model |

2PG0425 |

2PG0640 |

2PG0740 |

2PG0850 |

2PG1060 |

2PG1260 |

2PG1560 |

|

Roller diameter(mm) |

Ф400 |

Ф600 |

Ф700 |

Ф800 |

Ф1000 |

Ф1200 |

Ф1500 |

|

Roller width(mm) |

250 |

400 |

400 |

500 |

600 |

600 |

600 |

|

Input Size(mm) |

≤25 |

≤25 |

≤25 |

≤25 |

≤30 |

≤30 |

≤30 |

|

Discharging Gate(mm) |

2-8 |

2-8 |

2-8 |

2-8 |

2-10 |

2-10 |

2-10 |

|

Processing capacity(t/h) |

5-10 |

10-20 |

15-30 |

20-40 |

30-50 |

40-70 |

60-110 |

|

Power Models |

Y132M-6 |

Y180L-6 |

Y200L-4 |

Y225M-4 |

Y250M-4 |

Y315M-6 |

Y315L-6 |

|

Motor power(kw) |

5.5×2 |

15×2 |

30×2 |

45×2 |

55×2 |

75×2 |

110×2 |

|

Total weight(t) |

2.2 |

5.9 |

9.8 |

13.5 |

17.2 |

28.5 |

39.3 |

6 Safety Guarantee

Buyers of goods sold through Hochang machinery will be subject to Workplace Health and Safety laws applying to the places in which those goods are used. These laws vary from country to country. It is the Buyers obligation to obtain all appropriate information on the safe use of the goods supplied. Some goods may require repair, overhaul or commissioning before use. Wherever possible, manufacturers instruction and information on use will be supplied. The Buyer must, however, ensure that it obtains all instructions and information directly from the manufacturer in relation to the safe and appropriate start up, operation and maintenance of the goods and that the information is relevant to the particular goods being used. Any information, manuals and instructions supplied to the Buyer must be verified by the Buyer with the manufacturer.