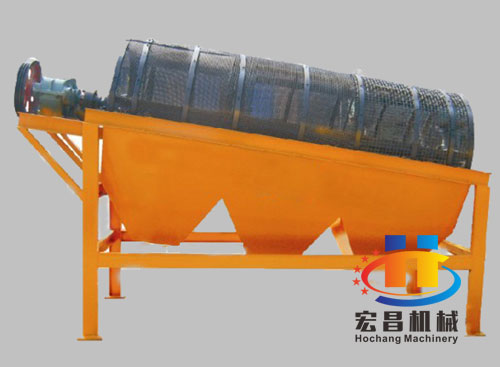

Trommel Screen is a dedicated screening equipment which is used in power plant, coking plant, building materials, metallurgy, chemical industry, mining and other industries.

2. Steady performance and low noisy;

3. Simple structure and convenient maintenance.

The roller is installed tipsily on the rack. The motor contact with the roller by the couple though reduction gears. The roller rotates around its axis drove by the motor. When the materials enter into roller, the materials on the surface of screen will overturn and roll as the screen. Because the whole slant set is running and turning. The qualified materials will be discharged out from the bottom of the roller. And the unqualified materials will run out from the opposite side. Materials overturn and run ceaselessly. So if there are materials locked in the hole of screen, they will be ejected, which can prevent the screen hole from blocking.

5. Technical parameter of Rotary drum screen/Trommel screen

| Type | Model and Specifications | Working Area(㎡) | Screen Layer | Max. Feeding Size(mm) | Processing Capacity(t/h) | Screen Size(mm) | Vibration Times | Power(kw) |

| Self-fixed Centre Vibrating Screen | 400×800 | 0.29 | 1 | 50 | 12 | 1-25 | 1500 | 1.1 |

| 400×800 | 0.29 | 2 | 50 | 12 | 1-15 | 1500 | 0.5 | |

| 800×1600 | 1.2 | 1 | 100 | 20-25 | 3-40 | 1430 | 2.2 | |

| 900×1800 | 1.52 | 1 | 60 | 20-25 | 1-25 | 1000 | 2.2 | |

| 900×1800 | 1.52 | 2 | 60 | 20-25 | 1-25 | 1000 | 2.2 | |

| 1250×2500 | 3.15 | 1 | 100 | 150 | 6-40 | 850 | 5.5 | |

| 1250×2500 | 3.15 | 2 | 150 | 150 | 6-40 | 1200 | 5.5 |

Zhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

Here is our best selling product.