Granulation rate: >93%

Capacity: 4-24t/h

Diameter:2.2m-3.6m

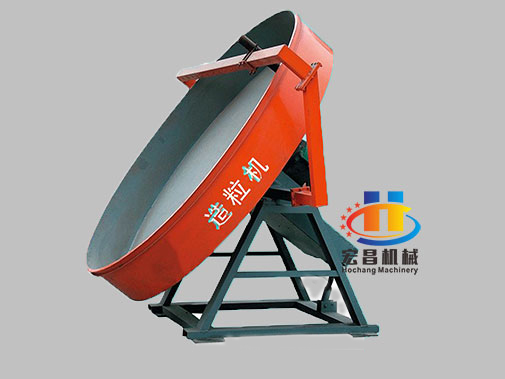

2) The disk of our disc granulator is designed with three discharging holes, which is convenient for intermittent production work. This largely reduces labor intensity and increases working efficiency.

3) The reducer and motor of our disc granulator are both driven by flexible belt, which ensures stable start, reduced impact force and longer service life.

4) Disc bottom is reinforced by multi-strip radiation steel plates, so it is wear resistant, durable and will never deform.

5) Thickened and strengthened granulator-base provides our disc granulator with stable operation. Therefore, our disc granulator is no need to be fixed by foundation bolts.

6) The main gear is processed by high frequency quenching technique. As a result, the lifetime of our disc granulator is greatly prolonged.

7) The granulator disk is lined with glass reinforced plastics, which is anti-corrosive and durable.

3. Working principle of Disc Granulator

|

Specification

(m) |

Rotation speed

(r/min) |

Production capacity

(t/h) |

Motor

(kw) |

Adjustment range of obliquity

|

Dimensions

(m) |

Total weight

(t) |

|

Φ2.2

|

14.25

|

4-8

|

7.5

|

35-55

|

2.8×2.75×2.58

|

3.2

|

|

Φ2.5

|

11.81

|

5-10

|

7.5

|

35-55

|

3.2×2.3×3

|

3.6

|

|

Φ2.8

|

11.21

|

12-16

|

7.5

|

35-55

|

3.4×2.6×3.1

|

4.1

|

|

Φ3.0

|

11.3

|

15-18

|

11

|

35-55

|

3.7×2.7×3.3

|

4.8

|

|

Φ3.2

|

9.6

|

15-20

|

11

|

35-55

|

3.9×2.7×3.4

|

5.6

|

|

Φ3.6

|

9.1

|

18-24

|

15

|

35-55

|

4.3×3.1×4.0

|

7.2

|

5 Safety Guarantee

Buyers of goods sold through Hochang machinery will be subject to Workplace Health and Safety laws applying to the places in which those goods are used. These laws vary from country to country. It is the Buyers obligation to obtain all appropriate information on the safe use of the goods supplied. Some goods may require repair, overhaul or commissioning before use. Wherever possible, manufacturers instruction and information on use will be supplied. The Buyer must, however, ensure that it obtains all instructions and information directly from the manufacturer in relation to the safe and appropriate start up, operation and maintenance of the goods and that the information is relevant to the particular goods being used. Any information, manuals and instructions supplied to the Buyer must be verified by the Buyer with the manufacturer.

Zhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

Here is our best selling product.