【Effective Volume】:1.7-230m³

【Power】:3-90kW

【Heat Source】:Coal, oil, natural gas, timber,biomass

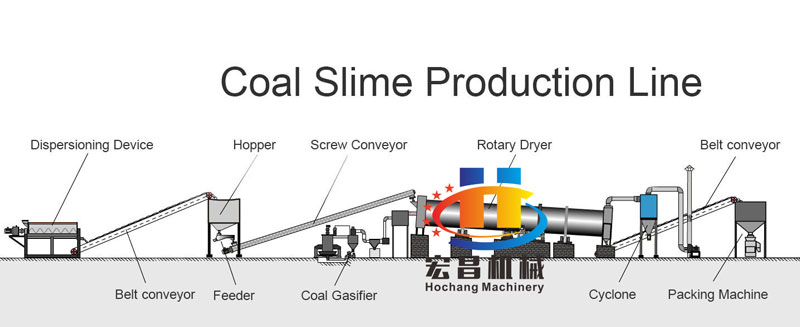

【Application】:Drying the concentrate by metallic and non-metallic magnetic separation,flotation,gravity concentration ,cement clay, coal slime, ore, steel slag, quartz sand, kaolin, bentonite, animal manure,gypsum,vinasse ,palm fiber,pks,sawdust etc.

|

Model |

Processing

Capacity |

Input

Moisture |

Output

Moisture |

Main Motor

for Sand Dryer |

Coal

Calorific Value |

Feedinlet

Temperature |

|

Ø1.5X14M |

10-12 |

20±3%

|

<10% |

15 |

>5500 KCAL/KG |

700±50℃ |

|

Ø1.8X14M |

15-18 |

20±3%

|

<10% |

18.5 |

>5500 KCAL/KG |

700±50℃ |

|

Ø2.0X16M |

20-25 |

20±3%

|

<10% |

18.5 |

>5500 KCAL/KG |

700±50℃ |

|

Ø2.2X18M |

25-30 |

20±3%

|

<10% |

22 |

>5500 KCAL/KG |

700±50℃ |

Zhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

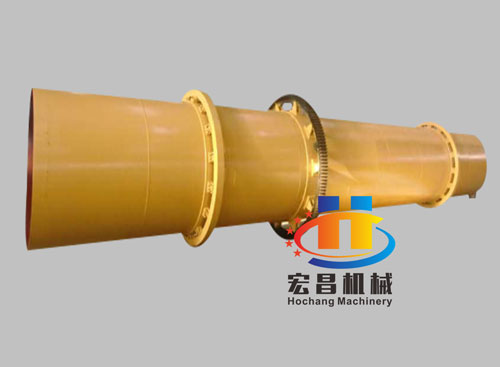

Here is our best selling product.