Why choose us ?

Our Value Message is “QUALITY IS OUR CULTURE .”

“WITH US YOUR MONEY IN SAFE AND YOUR BUSINESS IN SAFE!”

1 .Competitive advantage Products

2.Confidentially Agreement“ Business Secret CONTRACT”

3.Quality Assurance CONTRACT

4.SMALL Order welcomed

5.After sales services 24x7

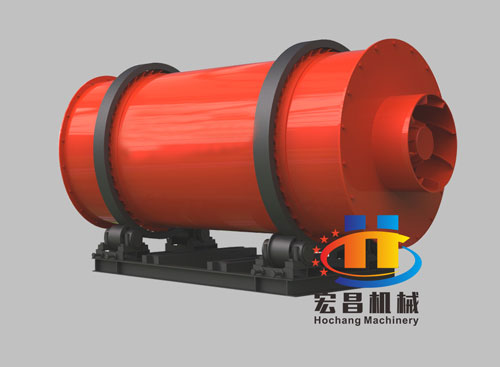

Ore powder dryer Overview

1 Brief Introduction

Zhengzhou Hochang Machinery is specialized in the production of various ore powder dryers, including manganese ore powder dryer, nickel ore powder dryer, cobalt ore powder dryer, tin powder dryer, chromium ore powder dryer, gold powder dryer and mercury powder dryer. The drying equipment is indispensable in the rare metal ore dressing operations, which effectively improves the ore dressing efficiency.

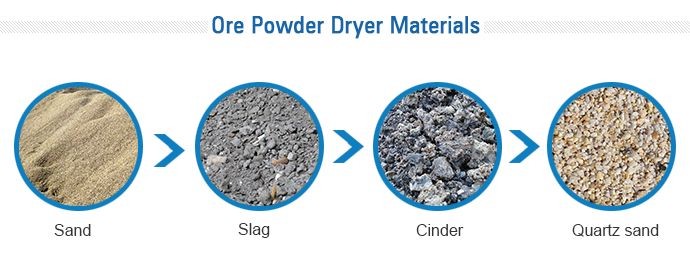

Ore powder dryer or mineral powder dryer is widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries, which is mainly used for drying wet and heavy materials such as mineral powder, slag, limestone, clay, sand, quartz sand, grain slag, etc. Hochang ore powder dryer can also be used for drying metal powder, so it can be called metal powder dryer.

2. Structure info.(Including Base Materials)

Ore powder dryer is an integrated unit consisting of a furnace to produce hot air, a rotary drum having 3 cylinders, one set of rigid supporting roll of the drum, one set of driving system of the drum, a cyclone, and a fan.

As a special design, the drying can take place in the two inner tubes, whilst cooling is performed in the outer shell.

1) Rotating cylindrical tube:boiler steel(G20)

2) Riding ring:cast steel ZG45#,surface hardness not less than HB170

3) Trunnion rollers:cast steel(ZG35)

3. Features of Ore Powder dryer

1. The needed investment is only 1/6 of foreign import product.

2. The final moisture of the materials is ensured to be below 0.5%, making it the first choice of dry-mixed mortar and slag powder production line.

3. The self heat preservation heat efficiency of the cylinder can reach as high as over 70%, thus improving the heat efficiency by 35%.

4. The fuel can be coal, gas and oil, and it can be used for drying lump, granulous and powdery materials whose granularity is below 20mm.

5. Compared with monocular dryer machine, its floor space is reduced by about 50%, infrastructure investment reduced by about 50% and electricity consumption reduced by 60%.

6. The needed final water content index can be easily regulated according to customers’ requirement.

7. The temperature of the air out is low and the service life of the dust removing equipment is long.

8. It needs no rack wheel and pinion driving, but uses riding wheel for transmission.

4. Ore powder dryer FLOW CHART

5. Technical parameter of Ore Powder dryer

|

Model |

Cylinder diameter

(m) |

Cylinder length

(m) |

Cylinder volume

(CBM) |

Rotation speed

(r/min) |

Highest inlet air temperature

(℃) |

Capacity

(t/h) |

Power

(kw) |

|

2*4.5m |

2 |

4.5 |

14.13 |

4—10 |

700—750℃ |

13—18 |

5.5*2 |

|

2.2*5m |

2.2 |

5 |

18.99 |

4—10 |

700—750℃ |

15—23 |

7.5*2 |

|

2.5*6m |

2.5 |

6 |

29.43 |

4—10 |

700—750℃ |

20—28 |

5.5*4 |

|

2.7*6.5m |

2.7 |

6.5 |

37.19 |

4—10 |

700—750℃ |

24—33 |

7.5*4 |

|

3.0*6.5m |

3.0 |

6.5 |

45.92 |

4—10 |

700—750℃ |

35—40 |

11*4 |

|

3.2*7m |

3.2 |

7 |

56.27 |

4—10 |

700—750℃ |

40—60 |

15*4 |

|

3.6*8m |

3.6 |

8 |

81.39 |

4—10 |

700—750℃ |

55—75 |

18.5*4 |

|

4.2*8m |

4.2 |

8 |

110.78 |

4—10 |

700—750℃ |

70—120 |

22*4 |

6. Safety Guarantee

Buyers of goods sold through Hochang machinery will be subject to Workplace Health and Safety laws applying to the places in which those goods are used. These laws vary from country to country. It is the Buyers obligation to obtain all appropriate information on the safe use of the goods supplied. Some goods may require repair, overhaul or commissioning before use. Wherever possible, manufacturers instruction and information on use will be supplied. The Buyer must, however, ensure that it obtains all instructions and information directly from the manufacturer in relation to the safe and appropriate start up, operation and maintenance of the goods and that the information is relevant to the particular goods being used. Any information, manuals and instructions supplied to the Buyer must be verified by the Buyer with the manufacturer.