Why choose us ?

Our Value Message is “QUALITY IS OUR CULTURE .”

“WITH US YOUR MONEY IN SAFE AND YOUR BUSINESS IN SAFE!”

1 .Competitive advantage Products

2 FULL REFUND In case of Bad Quality OR LATE Delivery

3.Confidentially Agreement“ Business Secret CONTRACT”

4.Quality Assurance CONTRACT

5.SMALL Order welcomed

6.After sales services 24x7

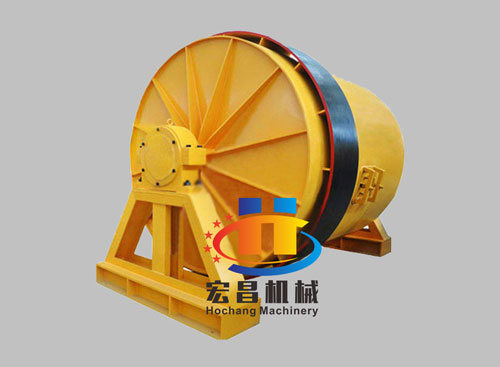

Ceramic ball mill Overview

1 Brief Introduction

Ceramic ball mill is a common ball mill in the dressing process. The structure of ceramic ball mill is different from intrinsic ball mill. The body and chassis are integration.Ceramic ball mill is applicable for the mixing and grinding the general and special materials. It is mainly used in ceramic glaze materials, superfine powder materials. The sizing of ceramic ball mill and liners as well as grinding media will be chosen according to the proportion and hardness of materials and capacity required. It is inlayed with ceramic, rubber and silica lining plate. Not only can dry grinding, also can be wet grinding.

You can put them down on the basic plane at a time when you install them. The main bearing uses double raw self-aligning roller bearing, which can reduces 30% energy consumption, improve its fine grit and processing capacity by 15 ~ 20% times.

2. Structure info.(Including Base Materials)

Ceramic ball mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control.

1.Hollow shaft: steel casting

2.Rotary rack wheel: casting gear hobbing

3.Cylinder: steel plates of 12-15mm thickness.

4.Lining plate: Ceramic

3. Quality guarantees

① …Utilization ratio,Product yield ratio Products,Qualification Ratio 100%.

② … Process inspection qualification rate 98%

③ … Products performance test qualification rate 100%

④ … Staff position competition specialized skill 100%

4. Features of Ceramic Ball mill (Grinding Mill )

1. Ceramic ball mill can be installed horizontally, vertically and slantingly.

2. It has the characteristics of large starting torque and vibration.

3. The performance of it is steady and reliable.

5. Working Principle of Ceramic Ball mill (Grinding Mill )

Hochang Ceramic ball mill is a horizontal cylindrical rotating device. It is a grate ball mill with two cells. Materials enter evenly into the first house from feeder machine to material hollow shaft. There are stepped lining plates, corrugated plates and ball mills in the cell. The barrel rotates, producing centrifugal force which brings ball mills at a certain height. Then the ball mills fall down, hitting and grinding materials. After coarse crushing in the first house, materials enter into second house though a single every warehouse. There are plane liners and ball mills in this house. Materials are grinded again in this house. The powders are discharged out by unload plate.

6. Technical parameter of Ceramic Ball mill (Grinding Mill )

|

Model |

Feeding capacity

(t/time) |

Shell rotation speed

(r/min) |

Reference motor

(kw) |

Liner material |

|

600×700 |

0.05 |

50 |

2.2 |

Chinaware,silicon,rubber or metal(the related motor power varied as per the different liner materials and grinding materials) |

|

800×600 |

0.075 |

42 |

3 |

|

900×1200 |

0.2 |

38.5 |

5.5 |

|

1300×1500 |

0.5 |

33 |

7.5 |

|

1500×1800 |

1.2 |

28.5 |

11 |

|

1800×2000 |

1.5 |

24 |

15 |

|

2600×2800 |

5 |

16.5 |

37 |

|

3000×3800 |

10 |

14.5 |

57.2 |

|

3200×4600 |

15 |

13.5 |

75 |

7 Safety Guarantee

Buyers of goods sold through Hochang machinery will be subject to Workplace Health and Safety laws applying to the places in which those goods are used. These laws vary from country to country. It is the Buyers obligation to obtain all appropriate information on the safe use of the goods supplied. Some goods may require repair, overhaul or commissioning before use. Wherever possible, manufacturers instruction and information on use will be supplied. The Buyer must, however, ensure that it obtains all instructions and information directly from the manufacturer in relation to the safe and appropriate start up, operation and maintenance of the goods and that the information is relevant to the particular goods being used. Any information, manuals and instructions supplied to the Buyer must be verified by the Buyer with the manufacturer.