Our Value Message is “QUALITY IS OUR CULTURE .”

“WITH US YOUR MONEY IN SAFE AND YOUR BUSINESS IN SAFE!”

1 .Competitive advantage Products

2 FULL REFUND In case of Bad Quality OR LATE Delivery

3.Confidentially Agreement“ Business Secret CONTRACT”

4.Quality Assurance CONTRACT

5.SMALL Order welcomed

6.After sales services 24x7

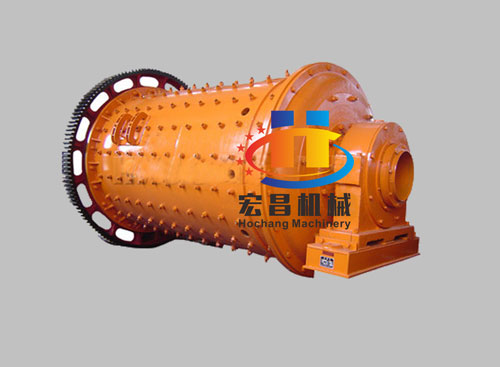

Rod mill Overview

1 Brief Introduction

Hochang brand rod mill has certain selective grinding effect in the grinding process because of the grinding medium and ore are line contacted. The product particle size is uniform, and excessive grinding ore grain is little .It is widely used in fine crushing and grinding operation of feldspar, quartz, abrasive, refractory material, cement, steel grit, slag, copper ore, iron ore, gold ore grit and other hard or brittle material. Rod mill is also used in sand making industries in recent years.

2. Structure info.(Including Base Materials)

ROD mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control.

1.Hollow shaft: steel casting

2.Rotary rack wheel: casting gear hobbing

3.Cylinder: steel plates of 12-15mm thickness.

4.Lining plate: high manganese steel and white iron

3. Quality guarantees

① …Utilization ratio,Product yield ratio Products,Qualification Ratio 100%.

② … Process inspection qualification rate 98%

③ … Products performance test qualification rate 100%

④ … Staff position competition specialized skill 100%

4. Features of Rod mill (Grinding Mill )

1. When the diameter of rod mill is less than 3200mm its conventional configuration is using rolling bearing instead of bearing bush sliding bearing energy saving 10% - 20%;

2. When the diameter of rod mill is more than 2700mm its conventional configuration is using slow driving for maintenance installing liner use;

3. When the diameter of rod mill is less than 1500mm its conventional configuration is monolithic large chassis reducing the installation time and installation requirements;

4. When the power of rod mill is less than 110 KW it uses cage asynchronous motor; When the power of rod mill is more than 110 KW it uses wire wound asynchronous motor; When the power of rod mill is more than 400 KW it can use high pressure (6 KV or 10 KV) asynchronous motor or the TDMK series high voltage (6 KV or 10 KV) synchronous motor;

5. Drum Feeder Spiral Feeder and Joint Feeder are available for meeting different working condition;

6. The gear lubrication mode has grease lubrication thin oil lubrication and automatic oil mist lubrication for meeting different working condition;

7. The bearing lubrication has manual and electric grease lubrication pump to select and it can realize lubrication automation;

8. There are a variety of liner plates type to select. Compared to A series standard type B series energy-saving type can save energy 10% - 20%.

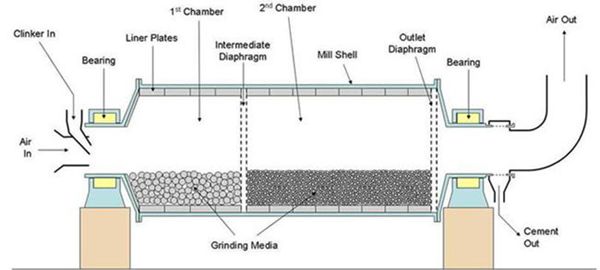

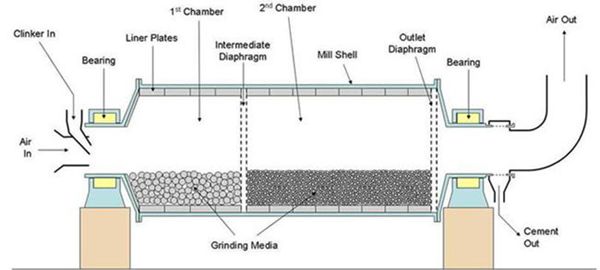

5. Working Principle of Rod mill (Grinding Mill )

Rod mill makes tube run with the help of the reduction gears drove by dynamo or the low speed synchronization electrical machine. There are steel balls in the tube. Steel balls are threw at a certain high by centrifugal and friction force and then fall down. The grinded material enters into the tube continuously and is crushed by the moving steel balls. After that, they are discharged from the machine naturally. Then they will start the following working process.

6. Technical parameter of Rod mill (Grinding Mill )

|

Model |

Shell Specifications (mm)

|

Shell rotation speed

(r/min) |

Feeding size

(mm) |

Discharging size

(mm) |

Processing capacity

(t/h) |

Power

(kw) |

Total weight

(t) |

|

Diameter |

Length |

|

MBS0918 |

900 |

1800 |

36-38 |

≤25 |

0.833-0.147 |

0.62-3.2 |

18.5 |

5.9

|

|

MBS0924 |

900 |

2400 |

36 |

≤25 |

0.833-0.147 |

0.81-4.3 |

22 |

6.7 |

|

MBS1224 |

1200 |

2400 |

36 |

≤25 |

0.833-0.147 |

1.1-4.9 |

30 |

13.9 |

|

MBS1530 |

1500 |

3000 |

29.7 |

≤25 |

0.833-0.147 |

2.4-7.5 |

75 |

19.8 |

|

MBS1830 |

1830 |

3000 |

25.4 |

≤25 |

0.833-0.147 |

4.8-11.6 |

130 |

34.9 |

|

MBS2130 |

2100 |

3000 |

23.7 |

≤25 |

0.833-0.147 |

14-35 |

155 |

46.5 |

|

MBS2136 |

2100 |

3600 |

23.7 |

≤25 |

0.833-0.147 |

19-43 |

180 |

48.7 |

|

MBS2430 |

2400 |

3000 |

21 |

≤50 |

0.833-0.147 |

25-65 |

245 |

59.7 |

|

MBS2736 |

2700 |

3600 |

20.7 |

≤50 |

0.833-0.147 |

32-86 |

380 |

92.5 |

|

MBS2740 |

2700 |

4000 |

20.7 |

≤50 |

0.833-0.147 |

32-92 |

400 |

95 |

|

MBS3245 |

3200 |

4500 |

18 |

≤50 |

0.833-0.147 |

64-180 |

630 |

149 |

7 Safety Guarantee

Buyers of goods sold through Hochang machinery will be subject to Workplace Health and Safety laws applying to the places in which those goods are used. These laws vary from country to country. It is the Buyers obligation to obtain all appropriate information on the safe use of the goods supplied. Some goods may require repair, overhaul or commissioning before use. Wherever possible, manufacturers instruction and information on use will be supplied. The Buyer must, however, ensure that it obtains all instructions and information directly from the manufacturer in relation to the safe and appropriate start up, operation and maintenance of the goods and that the information is relevant to the particular goods being used. Any information, manuals and instructions supplied to the Buyer must be verified by the Buyer with the manufacturer.