Why choose us ?

Our Value Message is “QUALITY IS OUR CULTURE .”

“WITH US YOUR MONEY IN SAFE AND YOUR BUSINESS IN SAFE!”

1 .Competitive advantage Products

2 FULL REFUND In case of Bad Quality OR LATE Delivery

3.Confidentially Agreement“ Business Secret CONTRACT”

4.Quality Assurance CONTRACT

5.SMALL Order welcomed

6.After sales services 24x7

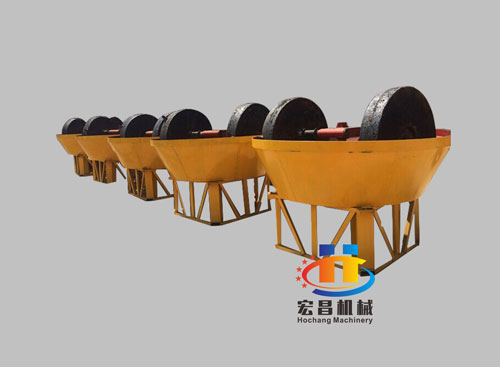

Wet pan mill Overview

1 Brief Introduction

Hochang Wet pan mill is widely used for selecting ferrous metals, nonferrous metals and nonmetals, as well as precious metals like gold and silver. It mainly consists of driving device, frame, water basin, grinding wheels and grinding base, etc. It grinds ores by wheel driving force: firstly, the power is transferred from the motor to the reducer, then to the horizontal shaft, and finally to the grinding wheel; the wheels then rotate anticlockwise. The wheels can revolve around the vertical shaft of the pan mill, at the same time; it can revolve on its own axis, while the grinding base will remain still. The ores are then pressed, rubbed and grinded repeatedly.

2. Structure info.(Including Base Materials)

Wet pan mill is mainly consists of driving device, frame, water basin, grinding wheels and grinding base, etc.

1. Grinding wheels: iron or stone

2.Pan: welded-steel

3. Features of wet pan mill

1. The grinding wheels mix up the ores and produce ore pulp while pressing and rubbing the ores.

2. The ores and water are evenly mixed, which makes the pulp density and other indexes stable.

3. After the grinding process, the monomers are taken to the upper surface of the pulp and discharged through the overflow outlet of the water basin. Meanwhile, the coarse ores sink to the bottom of grinding base, being grinded continuously till they reach the required fineness.

4. The screening mesh set up at the overflow outlet of the water basin classifies the ore fineness strictly to avoid the over-grinding and uneven fineness, which helps create better condition for next working process.

4. Technical parameter of wet pan mill

|

Model |

Specification |

Input size(mm) |

Rotate Speed (r/min) |

Powder(kw) |

Weight(t) |

|

1600A |

1600×400×200×500±20mm |

<30mm |

20-22 |

25KW |

14.5 |

|

1500A |

1500×350×200×460±20mm |

20-22 |

22KW |

13.5 |

|

1500B |

1500×350×150×460±20mm |

20-22 |

22KW |

12.3 |

|

1500C |

1500×300×150×420±20mm |

20-22 |

22KW |

11.3 |

|

1400A |

1400×250×150×350±20mm |

16-18 |

18.5kw |

8.5 |

|

1400B |

1400×250×150×350±20mm |

21-23 |

18.5kw |

8.5 |

|

1350A |

1350×250×150×350±20mm |

16-18 |

18.5kw |

8 |

|

1350B |

1350×250×150×350±20mm |

21-23 |

18.5kw |

8 |

|

1300A |

1300×250×150×350±20mm |

16-18 |

15kw |

7.5 |

|

1300B |

1300×250×150×350±20mm |

21-23 |

15kw |

7.5 |

|

1200A |

1200×200×80×250±20mm |

17-19 |

7.5kw |

5.5 |

|

1200B |

1200×200×80×250±20mm |

23-25 |

7.5kw |

5.5 |

|

1100A |

1100×200×80×250±20mm |

17-19 |

7.5kw |

5 |

|

1100B |

1100×200×80×250±20mm |

23-25 |

7.5kw |

5 |

|

1000 |

1000×200×80×250±20mm |

13-15 |

5.5kw |

4.5 |

5 Safety Guarantee

Buyers of goods sold through Hochang machinery will be subject to Workplace Health and Safety laws applying to the places in which those goods are used. These laws vary from country to country. It is the Buyers obligation to obtain all appropriate information on the safe use of the goods supplied. Some goods may require repair, overhaul or commissioning before use. Wherever possible, manufacturers instruction and information on use will be supplied. The Buyer must, however, ensure that it obtains all instructions and information directly from the manufacturer in relation to the safe and appropriate start up, operation and maintenance of the goods and that the information is relevant to the particular goods being used. Any information, manuals and instructions supplied to the Buyer must be verified by the Buyer with the manufacturer.